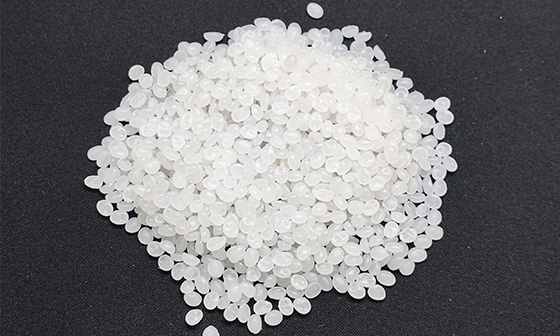

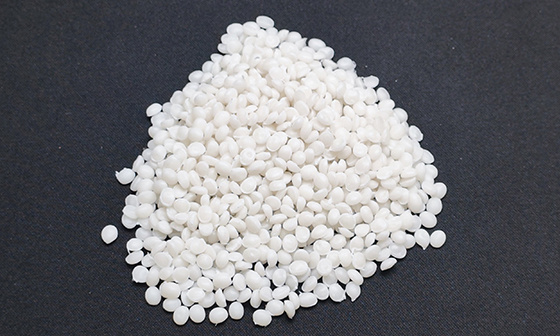

KML 919H

Classification:

Product Introduction

Product Details

● Product description

KML 919H is a high-efficiency smooth masterbatch for CPE casting/blowing film. By adding KML 919H, the film can be endowed with excellent smoothness, scratch resistance, oxidation resistance, low migration and low precipitation, and can be used for solvent-free compounding. It is generally used together with an anti-blocking masterbatch or with a resin containing an anti-blocking component.

● Physical properties

| Melt index (190 ℃/2.16kg) | g/10min | 19 |

| Bulk density | Kg/m3 | 550 |

| Moisture content | ppm | <1500 |

| active ingredient content | % | 5 |

The above is only typical data, not as a standard at the time of sale.

● Application

Widely used in gravure printing film, food packaging film, multi-layer co-extrusion film, high light transmission film, etc.

● Method of use

The amount of the masterbatch is determined according to the customer's specific requirements for the coefficient of friction of the film. The addition amount of KML 919H is controlled at 1% ~ 4%.

Use according to the normal addition ratio, which has a slight effect on corona treatment, heat sealing and adhesive properties. However, if used in combination with other migratory additives, such as antistatic agents or ultraviolet light stabilizers, special care is required.

● Food approval

KML 919H can be applied to food packaging according to the following requirements

FDA No Restrictions

● Packaging & Storage

KML 919H is packed in polyethylene bags of 25kg each, covered with shrink film and carried on pallets. For optimum performance, the storage period should preferably not exceed 6 months at a temperature of 25°C.

Keywords: