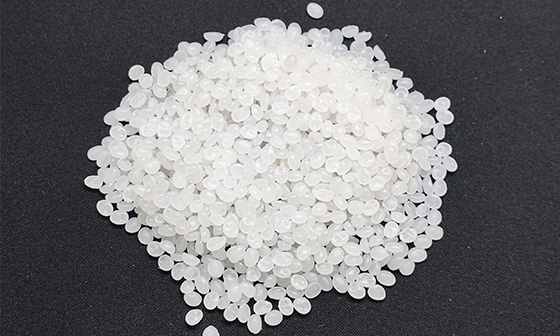

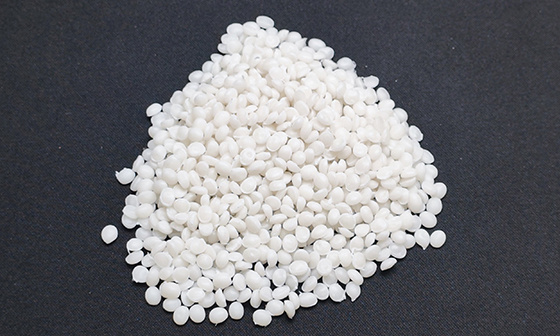

KML 816A

Classification:

Product Introduction

Product Details

● Product description

KML 816A is used for the anti-blocking masterbatch of PE film, which gives the film excellent anti-blocking property by adding natural silicon. It has a slight effect on the optical properties of the film.

The addition of the masterbatch can effectively improve the anti-blocking property of the film during winding and eliminate the generation of bubbles during winding, and effectively improve the customer's slitting and use efficiency.

● Physical properties

| Melt index (190 ℃/2.16kg) | g/10min | 6 |

| Bulk density | kg/m3 | 545 |

| Moisture content | ppm | <1500 |

| active ingredient content | % | 20 |

The above is only typical data, not as a standard at the time of sale.

● Application

KML 816A is one of the most commonly used anti-blocking masterbatch, with good anti-blocking effect and stable friction coefficient. It is mainly used for single-layer or multi-layer co-extruded films. It is suitable for FFS heavy-duty packaging film. In order to improve the uniformity of mixing, please use a mixing machine to mix or automatic metering and feeding during use.

● Method of use

Blocking is defined as the adhesion of two connected films to each other, which occurs during manufacture, storage, post-processing or use. Blocking may be caused by winding the roll film too tightly or the film being compressed when stacked, which is more likely to occur.

The adhesion test method of the film is to adjust the sample under controlled temperature and pressure conditions, and then test the force required to separate the two layers of film. It is recommended to add a ratio:

| 25 | 50 | 75 | 100 | 150 | |

| KML 816A | |||||

| - | 2.0% | 1.5% | 1.0% | 0.7% |

● Food approval

KML 816A can be applied to food packaging FDA unlimited according to the following requirements

● Packaging & Storage

KML 816A is packed in polyethylene bags of 25kg each, covered with shrink film and carried on pallets. For optimum performance, the storage period should preferably not exceed 12 months at a temperature of 25°C.

Keywords: