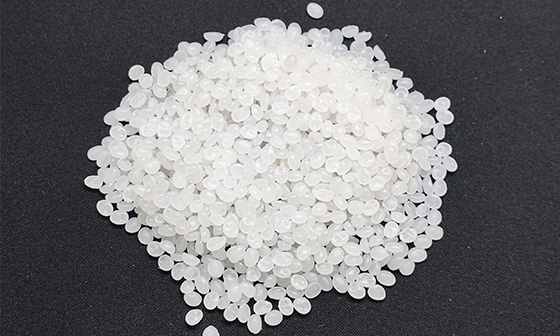

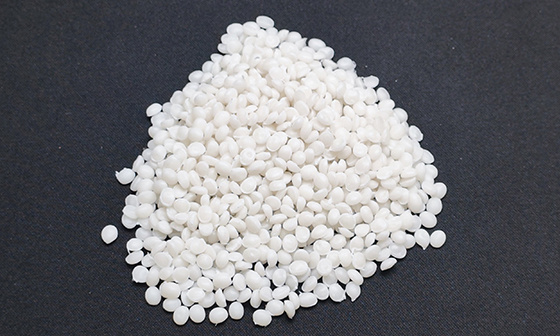

KML 925

Classification:

Product Introduction

Product Details

● Product description

KML 925 is a compound functional masterbatch with anti-adhesion and smooth effect. High purity synthetic silicon opening agent and imported erucamide slip agent are added to make the processed film have efficient anti-adhesion and smooth effect, and can obtain better optical performance.

● Physical properties

| Melt index (190 ℃/2.16kg) | g/10min | 8 |

| Bulk density | kg/m3 | 580 |

| Moisture content | ppm | <1500 |

| active ingredient content | % | 15 |

The above is only typical data, not as a standard at the time of sale.

● Application

According to the customer's requirements for performance, the addition amount is 0.5~3.0%, and the recommended dosage is generally as follows:

| Film thickness (μm) | 25 | 50 | 75 | 100 | 150 |

| Addition amount (%) | 3.0 | 2.0 | 1.0 | 0.7 | 0.5 |

Note: The specific amount of addition, please customers according to different film thickness and smooth requirements through experiments to obtain the amount of this recommend is for reference only. If an excessive amount of KML 925 is added, it may cause problems such as screw slippage, poor adhesion of printing ink, poor heat sealing and poor adhesive strength. It is necessary to evaluate the amount of addition. And anti-static, UV stable masterbatch and other mixed use may produce smooth synergistic effect.

● Food approval

KML 925 can be applied to food packaging according to the following requirements

FDA No Restrictions

● Packaging & Storage

KML 925 are packed in polyethylene bags of 25kg each, and the whole is covered with shrink film and carried on pallets. For better performance, the storage period should not exceed 12 months at a temperature of 25°C.

Keywords:

Antiblock&Slip Masterbatch

smooth

amount