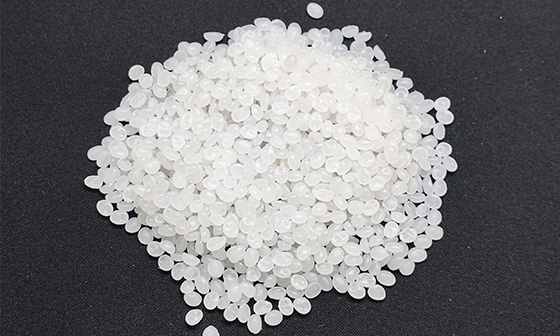

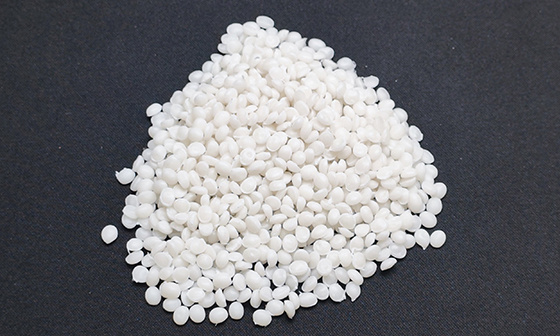

KML 925H

Classification:

Product Introduction

Product Details

● Product description

KML 925H is a polyethylene CPE casting/blown film special composite masterbatch with both anti-blocking and smooth effects. It has the characteristics of high temperature resistance, low precipitation, good transparency, strong scratch resistance and excellent oxidation resistance. The film produced by using this masterbatch has a smooth performance that is less affected by changes in ambient temperature, curing conditions and adhesive when used in solvent-free compounding, and can maintain a stable smooth effect after compounding.

● Physical properties

| Melt index (190 ℃/2.16kg) | g/10min | 15 |

| Bulk density | kg/m3 | 580 |

| Moisture content | ppm | <1500 |

| active ingredient content | % | 17 |

The above is only typical data, not as a standard at the time of sale.

● Application

The addition amount is generally controlled at 1.0%~ 5.0%. The specific addition amount of customers can be determined according to their own actual situation, sample preparation, please pay attention to the friction coefficient after the composite.

● Food approval

KML 925H can be applied to food packaging according to the following requirements

FDA No Restrictions

● Packaging & Storage

KML 925H is packed in polyethylene bags of 25kg each, covered with shrink film and carried on pallets. For optimum performance, the storage period should preferably not exceed 6 months at a temperature of 25°C.

Keywords: