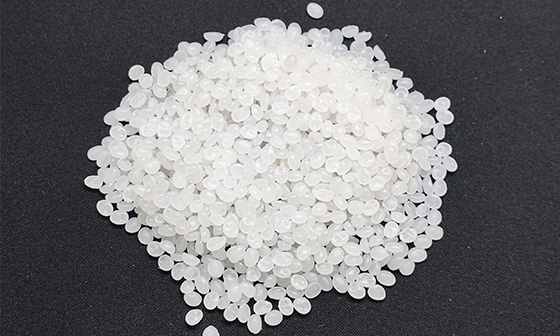

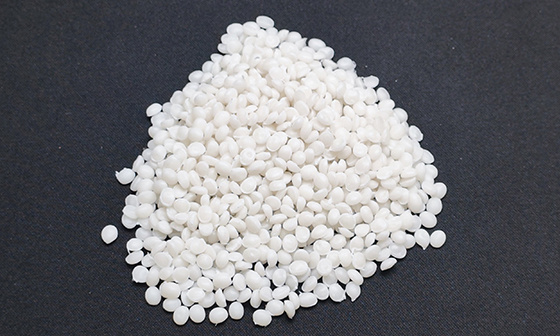

KML PPA ZH5

Classification:

Product Introduction

Product Details

● Product description

KML PPA ZH5 is a processing masterbatch for casting equipment. By adding the masterbatch, it can effectively reduce the adhesion between melt and equipment, increase self-cleaning, improve product smoothness and brightness, reduce or eliminate head precipitates, and extend continuous production time.

The masterbatch is mainly used to eliminate melt fracture, and the maximum use temperature can reach about 350 ℃.

● Physical properties

| Melt index (190 ℃/2.16kg) | g/10min | 3 |

| Bulk density | kg/m3 | 520 |

| Moisture content | ppm | <1500 |

| active ingredient content | % | 5 |

The above is only typical data, not as a standard at the time of sale.

● Method of use

KML PPA ZH5 has lower melt pressure and melt temperature. The equipment used for the first time needs 10-60 minutes of onset time, and the dosage of masterbatch can also be increased to shorten the onset time. In order to shorten the onset time, it is recommended to use 5.0 for the first time, and the amount of masterbatch normally added is generally controlled at 1.0. In addition, the smaller the gap between the die heads, the higher the required dosage.

KML PPA ZH5 does not have a negative impact on heat treatment and corona treatment, so it does not affect the adhesion or bonding properties of the printing ink.

● Food approval

KML PPA ZH5 can be applied to food packaging according to the following requirements

FDA No Restrictions

● Packaging & Storage

KML PPA ZH5 is packed in polyethylene bags of 25kg each, covered with shrink film and carried on pallets. For optimum performance, the storage period should preferably not exceed 12 months at a temperature of 25°C.

Keywords: