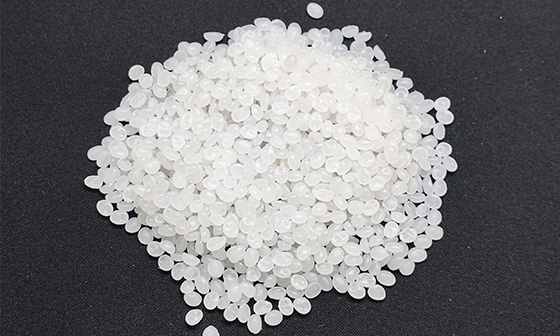

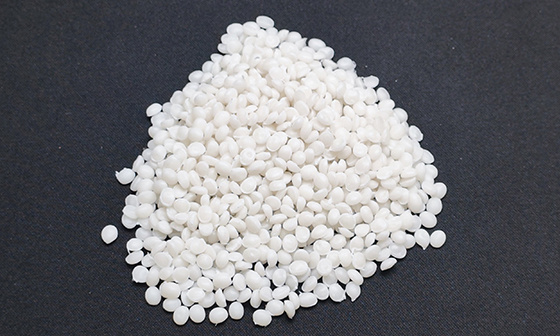

KML 801K

Classification:

Product Introduction

Product Details

● Product description

KML 801K is a high-efficiency amine-free functional masterbatch with polyethylene as the carrier and excellent antistatic effect. It has low precipitation and less migration, strong thermal stability, good compatibility and lasting antistatic effect, and also has good antistatic effect under low humidity climate conditions.

● Physical properties

| Melt index (190 ℃/2.16kg) | g/10min | 12 |

| Bulk density | kg/m3 | 530 |

| Moisture content | ppm | <1500 |

| active ingredient content | % | 6 |

The above is only typical data, not as a standard at the time of sale.

● Application

KML 801K is generally used to produce some thick heavy-duty plastic packaging that requires low friction coefficient, and is widely used in powder packaging, dustproof packaging and other antistatic products.

● Method of use

Antistatic masterbatch KML 801K can choose to add 2.0%~ 5.0%, depending on the type of resin and the thickness of the parts:

| Film use | LDPE 、 LLDPE | 1.0~2.0% | HDPE | 3.0~5.0% | |

| Molded parts | LDPE 、 LLDPE | 3.0~3.0% | HDPE | 3.0~5.0% | |

| blown film | HDPE | 3.0~5.0% | |||

The antistatic agent of antistatic masterbatch KML 801K needs to migrate to the surface to work. Therefore, the conditions of heat sealing and printing may need to be adjusted. Products that need heat sealing or printing should be given priority to on-line coextrusion. Improving corona or flame treatment is beneficial to printing; Reduce heat sealing speed; Use resin without or with a small amount of smooth components.

Note: High surface area pigments (such as carbon black) may slow down the migration effect of the antistatic agent, and even inhibit its antistatic effect under high load conditions.

● Food approval

KML 801K can be applied to food packaging according to the following requirements

FDA No Restrictions

● Packaging & Storage

KML 801K is packed in polyethylene bags of 25kg each, covered with shrink film and carried on pallets. For optimum performance, the storage period should preferably not exceed 6 months at a temperature of 25°C.

Keywords:

Antistatic Masterbatch

antistatic