Products

——

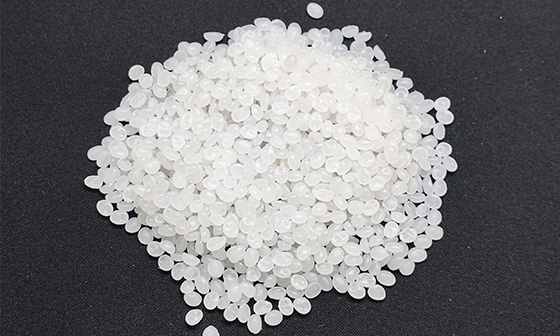

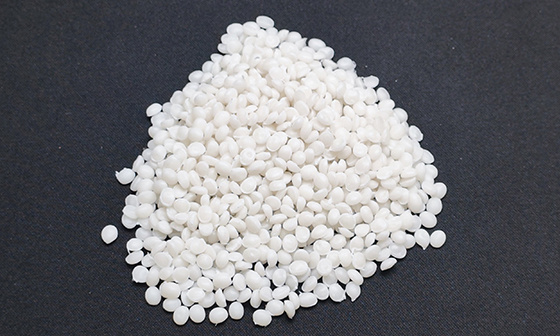

KML 16098

Classification:

Product Introduction

Product Details

● Product description

KML 16098 is a kind of polyethylene as the base material, used for PE film coloring milky white masterbatch, titanium dioxide content of 70%, through the careful selection of materials and excellent equipment mixing to achieve fine dispersion and high hiding power.

● Physical properties

| Melt index (190 ℃/2.16kg) | g/10min | 13 |

| Bulk density | kg/m3 | 1180 |

| Moisture content | ppm | <1500 |

| active ingredient content | % | 70 |

The above is only typical data, not as a standard at the time of sale.

● Application

The masterbatch can be used for blown film, blow molding, injection molding and cast film, and is particularly suitable for applications requiring high hiding power and low add-on.

● Method of use

KML 16098 is particularly suitable for films that require only a small addition ratio to obtain high hiding, and can also be used for injection molding and blow molding articles.

In blow molding and injection molding on the general amount of 1.0 to 3.0%. If the user has special requirements, the addition amount of 20% also has good dispersion, the masterbatch in the FFS film layer addition of 3.0 to 5.0.

● Food approval

KML 16098 can be applied to food packaging according to the following requirements

FDA No Restrictions

● Packaging & Storage

KML 16098 are packed in polyethylene bags of 25kg each, and the whole is covered with shrink film and carried on pallets. For optimum performance, the storage period should preferably not exceed 12 months at a temperature of 25°C.

Keywords:

Message feedback

If you are interested in our products

You can call the service hotline directly +86-393-4405588

Pioneering and Innovative, Pragmatic and Effective

Comaler plastics, dedicated to the majority of customer service

Address: East of Xindong Road and Weidu Road, Hualong District, Puyang City, Henan Province

E-mail: Km@Comaler.com