Products

——

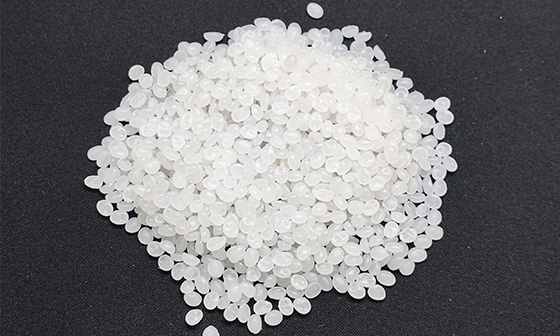

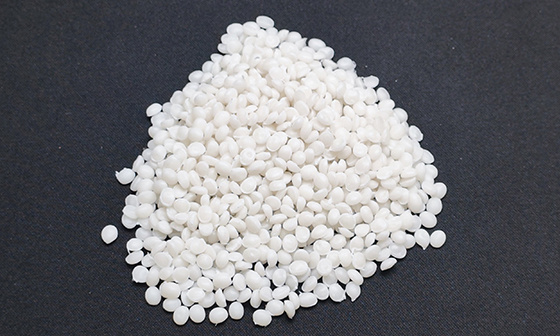

KML AO3580

Classification:

Product Introduction

Product Details

● Product description

KML AO3580 is a polyethylene antioxidant masterbatch for stabilizing LDPE, HDPE, LLDPE and EVA. The material stays in the extruder at high temperature for a long time may cause oxidation, crosslinking, gel formation, particle carbonization or reduce its mechanical properties, and its performance can be improved by adding antioxidant masterbatch.

KML AO3580 is especially suitable for the stable system of cast film, and the use temperature can be as high as 320 ℃.

● Physical properties

| Melt index (190 ℃/2.16kg) | g/10min | 15 |

| Bulk density | kg/m3 | 520 |

| Moisture content | ppm | <1500 |

| active ingredient content | % | 6 |

The above is only typical data, not as a standard at the time of sale.

● Method of use

The addition ratio of KML AO3580 mainly depends on the processing temperature and the residence time of the material in the machine.

| Improved stability | 1.0~2.0% |

| Reboot the extruder | 2.0~3.0% |

| Recycling | 2.0~3.0% |

| Stable lease for vacation downtime | 5.0~10.0% |

● Food approval

KML AO3580 can be applied to food packaging according to the following requirements

FDA No Restrictions

● Packaging & Storage

KML AO3580 is packed in polyethylene bags of 25kg each, covered with shrink film and carried on pallets. For better performance, the storage period should not exceed 12 months at a temperature of 25°C.

Keywords:

Antioxidant Masterbatch

Message feedback

If you are interested in our products

You can call the service hotline directly +86-393-4405588

Pioneering and Innovative, Pragmatic and Effective

Comaler plastics, dedicated to the majority of customer service

Address: East of Xindong Road and Weidu Road, Hualong District, Puyang City, Henan Province

E-mail: Km@Comaler.com