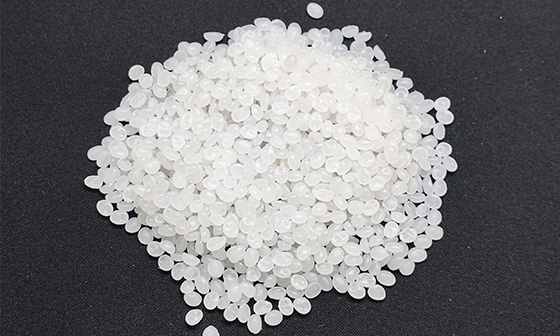

KML UV96

Classification:

Product Introduction

Product Details

● Product description

KML UV96 is a low melt polymer sterically hindered amine in LDPE. As a UV-stabilized masterbatch, the degradation rate depends on weather conditions, thickness, polymer type and haze or other pigments or additives formulated into resins, compatible with EVA, LDP, HDPE and LLDPE, is a polyethylene film used to resist photocatalysis or thermal decomposition stability of functional masterbatch. It is based on low melting point low density polyethylene, containing 20% of the polymerization space hindered amine.

● Physical properties

| Melt index (190 ℃/2.16kg) | g/10min | 6 |

| Bulk density | kg/m3 | 520 |

| Moisture content | ppm | <1500 |

| active ingredient content | % | 20 |

The above is only typical data, not as a standard at the time of sale.

● Application

The addition rate of KML UV96 depends on the climatic conditions of the local country where the film is exposed. The amount of sunlight in each region of the world is expressed in KLy. Central Europe: 90KLy Sicily: 170KLy Southern France: 140KLy Saudi Arabia: 220KLy Florida, Indonesia: 160Kly. The recommended dosage for KML UV96 is as follows:

| Thickness (μm) | 80 KLy | 100 KLy | 120 KLy | 140 KLy | 160 KLy | 180 KLy | |

| 30 | 1% | 1.5% | 2% | 2.5% | 3% | 3.5% | |

| 50 | 0.75% | 1% | 1.25% | 1.5% | 1.75% | 2% | |

| 80 | 0.5% | 0.75% | 1% | 1.25% | 1.5% | 1.75% | |

The stability of KML UV96 is affected by many factors, and it must be recognized that the values expressed above only represent the masterbatch under ideal conditions. The above data is for reference only.

● Food approval

KML UV96 can be applied to food packaging according to the following requirements

FDA No Restrictions

● Packaging & Storage

KML UV96 is packed in polyethylene bags of 25kg each, and the whole is covered with shrink film and carried on pallets. For better performance, the storage period should not exceed 12 months at a temperature of 25°C.

Keywords:

UV-Stabilizer Masterbatch

polymer